Standard Three Axes Servo Driven Robot ST3-S2

Categories : Industrial Robots

The ST3-S industrial robotic arm is designed for rapid and precise removal of products from injection molding machine, and place them at desired locations. Apply to 2-plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine with clamping force under 300 tons.

Servo Driven Beam Robots - Bomarc series

Categories : Industrial Robots

Bomarc Series injection molding robots is applicable to all types of horizontal injection machine of 50T to 600T for take-out of products and sprues. Vertical stroke is 600mm to 1200mm. The traverse axle is driven by inverter motor and can also be driven by AC servo motor as optional. Vertical axle and kick axle are all driven by cylinders, which is cost-effective.

Longitudinal Three Axes Servo Drive Robot-SL3

Categories : Industrial Robots

The SL3 industrial robot arm is designed for rapid and precise removal of product, sprue and runner from injection molding machine. It is suitable for 2-plate mold or hot runner system mold, and capable of arranging, stacking, quality checking and in mold placement.

Five Axes Servo Driven Robot - ST5

Categories : Industrial Robots

The ST5 industrial robotic arm is designed for rapid and precise removal of sprue and products from injection molding machine, and place them at desired locations. Standard and telescopic arms are selectable to cooperate with 2 plate mold, 3 plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine under 3600T clamp force.

Plastic Machine Controllers - AR Series HMI

Categories : Hot Runner Systems

ARICO - The Best Solution Of AR Series - HMI ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision AR Series - HMI and related application equipment, but also provides high-quality AR Series - HMI with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with AR Series - HMI, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

Micro Processor Controllers

Categories : Control Equipment

ARICO - The Best Solution Of Micro Processor Controllers ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision Micro Processor Controllers and related application equipment, but also provides high-quality Micro Processor Controllers with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with Micro Processor Controllers, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

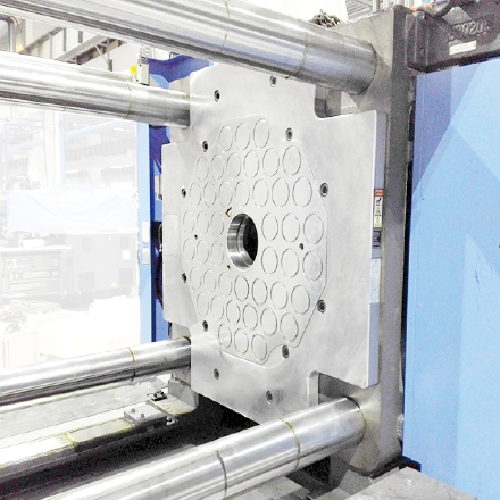

Magnetic Clamping System

Categories : Mold Changing Systems

Electro-permanent magnetic quick mold change system is perfectly for 50~4000 Tons injection molding machines.The latest magnetic structure and outstanding design of magnetic circuit achieves a 20% and more of the magnetic force than traditional magnetic temperate design Electro-permanent magnetic quick mold change system provides much greater improvement on mold change efficiency. It performs less than 3 minutes for mold changing of general injection molding machine. For large size machine, it will shorten the mold changing time from 2 hours down to 10 minutes. The system requires just single operator for mold changing job. Without any tool, operator can easily handle this system beyond the safety distance of the machine. The system can reduce labor cost and man power waste greatly. 8 special safety function designs can fully protect machine operation safety.

EASYLINK|IoT Injection Molding

Categories : Industrial Software

IoT injection molding|EASYLINK smart system is integrate and processes all data of the machine for these functions: [Production Monitoring] [Quality Management] [Abnormal Inspection] [Smart Management] [ Work order distribution] [ Electronic report] The characteristic of production management, advance the function is include the real-time video monitor, e-mail or LINE communication software notification function, and machine / operator management, and intelligent management to solve the difficulty of the factory management. The Internet of Things for injection molding system|EASYLINK will merge and process all the data on your plastic injection related machines to provide the above six major IoT functions. Arico

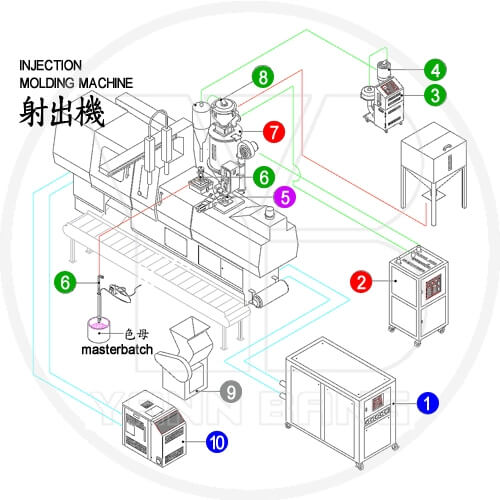

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

Side Entry Robot SSE

Categories : Industrial Robots

SSE industrial robot is designed for thin-walled products which cycle time below 6sec. With its high speed features can improve the production efficiency. Suitable for injection molding machine with clamping force under 400 tons.

Austrian KEBA controller I series control unit

Categories : Control Equipment

EUROPEAN QUALITY ELEMENTS ENSURE PERFECT PERFORMANCE FOR IMM ● High-performance 32 bit processor ● All I/Os for standard injection molding machines ● PWM current outputs for direct control of proportional valves ● Optimized digital outputs for hydraulic switching valves ● Thermocouple inputs for different types of sensors ● Pulse input for screw speed ● Ethernet connection for host computer ● USB connection for printer, modem, USB stick, etc.

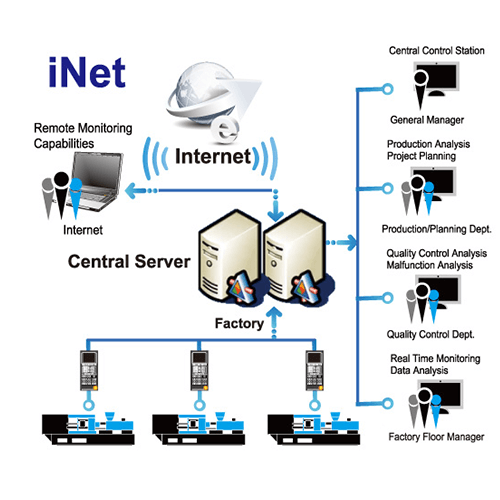

Software Products and Service System-iNET

Categories : Control Equipment

iNet is a complete injection molding machine factory network management solution to help plastic plant production and management. With network connectivity, iNet can be a bridge between management and the production site and also enables administrators to conduct global operations, providing customers with new trends in the management and controlling the global trend. iNet is a necessary weapon for enterprises towards successful information technology.